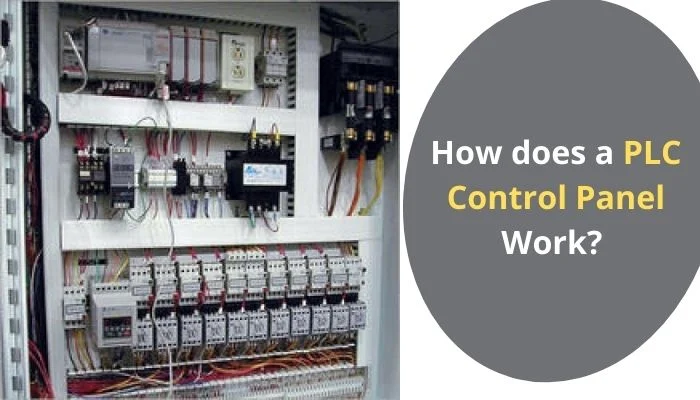

A programmable logic controller (PLC) is a powerful computer used in factories and industrial plants to control motors, pumps, circuit breakers, fans, lights, and other machinery. In this post, we will discuss how a PLC control panel works? and what are the advantages of a PLC control panel?

|

| PLC Control Panel |

What is a Programmable Logic Controller and How does a PLC Control Panel Work?

Do you know what a Programmable Logic Controller is? How does a PLC control panel work? What are the steps in the operation of the PLC? So, in this post, We walk you through these questions and answer them. And at last, we discuss the benefits of the PLC control panel that is made by a reliable Control Panel Manufacturing Company. So, let’s start with this guide.

It is impossible to overstate the importance of a control panel design that is both strong and dependable. Commercial control panels make it possible to handle the features and capabilities of both hardware and software in a more effective manner. All of the main components of a control panel should be well-organized and optimized in order to provide optimal performance at all times.

PLC is an abbreviation for the Programmable Logic Controller. PLC is a ruggedized computer used in factories and industrial plants to control motors, pumps, circuit breakers, fans, lights, and other machinery. A PLC can automate a specific industrial process, machine function, or even an entire production line.

PLC control panels are highly efficient. They have the ability to provide more output while using less power than previous models. PLC control panel solutions simplify the maintenance of systems while also lowering the expenses involved with different projects.

Large rack-mounted modular devices with thousands of I/O, which are often networked to other PLC and SCADA systems, can range from small modular devices with tens of inputs and outputs (I/O), in a housing that is integral to the processor, to small modular devices with tens of I/O, in a housing that is integral with the processor. These materials maintain their corrosion and rust resistance even when exposed to highly reactive conditions. The complexity and redundancy provided by PLCs for mission-critical applications, as well as their ability to resist harsh conditions, make them ideal for use in the industrial sector.

Control Panel Manufacturer specializes in the design, production, supply, and export of a comprehensive line of PLC Control Panels. Because of their excellent strength-to-weight ratio, the control panels are able to be made lightweight without sacrificing their structural integrity. The panels are available as stand-alone units, self-standing units, and wall-mounted units.

PLC PCB is gaining popularity nowadays as an industrial computer for high-reliability control. As we know PCBA is a completed PCB assembly that contains all of the necessary electronic components for the board to function as needed. One of the best benefits of using FS PCBA is that it gives good flexibility to place required components and fix them at a specific position.

How does a PLC Control Panel Work?

In the functioning of all PLCs, there are four fundamental steps: input scanning, program scanning, output scanning, and housekeeping. These stages are repeated again and over again in a looping pattern.

There are four steps in the operation of the PLC.

1.) Scan of the Input

The status of all input devices that are connected to the PLC is detected by this function.

2.) Scanner for programs

This function executes the logic of the user-created program.

3.) Scan of the Output

Activates or deactivates the operation of all output devices that are linked to the PLC.

4.) General housekeeping

Communication with programming terminals, internal diagnostics, and other tasks are performed during this phase.

Power distribution controllers (PLCs) are sophisticated and powerful computers that take in data, execute logic on the data in the CPU, and then switch on or off outputs depending on the logic. Consider the following scenario as an example:

The CPU keeps track of the state of the various inputs (for example, proximity sensor off, valve 40 percent open, etc.)

The CPU takes the information it receives from the inputs and applies logic to the information it receives.

The CPU controls the outputs in accordance with the logic (for example, turn off motor, open valve, and so on.)

Control Systems Engineers have created communication software that allows PLC Panels to communicate with one another across a network using a variety of different protocols. With PLC-based Panels, HMI/MMI are given to the operator in order to display different messages and controls of the process plants on a touch screen. In order to maintain effective control over the system.

Now, let’s see what are the benefits of the PLC control panel.

Benefits of the PLC control panel

It is adaptable in nature: A single PLC model may be utilized for a variety of activities depending on the requirements.

Installation and troubleshooting are simple: When compared to PLC-based control panels, hard-wired relay-based systems need more time to install and troubleshoot.

Availability of big contacts: PLC programming tools have an inbuilt large number of contacts that may be utilized for every change that is caused in various applications, which makes them extremely versatile.

It is more affordable than other controller or relay-based systems because of the advanced technology and wide-scale manufacturing of PLCs.

Simulation functionality: PLC programming software has simulation functionality by default.

Simple programming techniques: The PLC is supplied with simple programming ways to program the PLC, such as Ladder or Boolean type of programming, to make programming easier.

Cheap maintenance costs: When compared to other types of control systems, such as relay-based or microcontroller-based systems, the maintenance costs of PLCs are relatively low.

documentation is simple for the programmer, who may simply create and print the PLC codes for future usage.

I hope you now understand how a PLC control panel works. If you have any questions, then comment.